the substrate for biofilm growth, facilitating the breakdown of organic matter and other pollutants. Among the most popular choices in bio media is the K1 MBBR media, a widely-used carrier due to its innovative design and proven performance in a variety of wastewater treatment applications.

This article delves into how K1 MBBR media works, the advantages it offers, and how it compares to other biofilm technologies in 2024.

How K1 MBBR Media Works

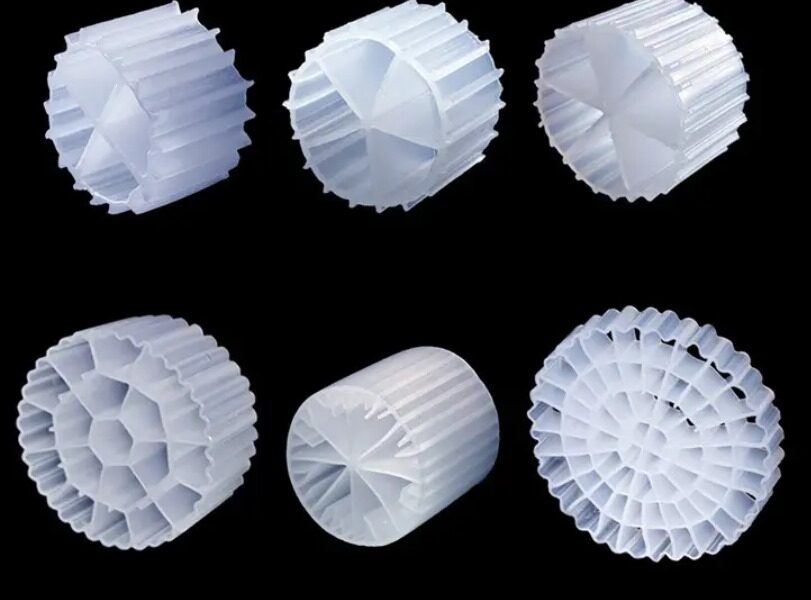

K1 MBBR media is a type of high-efficiency plastic carrier specifically designed for use in MBBR systems. It is distinguished by its cylindrical shape and intricate internal structure, which creates a high surface area for biofilm attachment. The media itself is typically made of high-density polyethylene (HDPE), which is buoyant and durable, ensuring long-term operation in wastewater treatment systems.

1. Biofilm Development

K1 MBBR media facilitates the formation of biofilm on its surface. The biofilm, consisting of microorganisms such as bacteria, adheres to the media and is responsible for breaking down organic pollutants in wastewater. The design of K1 media provides numerous small crevices and pockets where biofilm can thrive, allowing for optimal biological activity.

2. High Surface Area-to-Volume Ratio

The efficiency of K1 media is largely due to its high surface area-to-volume ratio. The media’s surface area is critical for biofilm attachment, with the increased surface area allowing for a greater microbial population to colonize the media. This directly enhances the system’s biological capacity, enabling it to treat higher concentrations of wastewater with a smaller footprint.

3. Continuous Movement

In an MBBR system, K1 media is continuously agitated by aeration or water flow within the reactor. This movement ensures that the media remains in constant contact with the wastewater, providing continuous treatment. The motion of the media also helps slough off excess biofilm, maintaining a healthy balance of microorganisms and preventing clogging or overgrowth.

4. Effective Oxygen Transfer

The cylindrical shape of K1 MBBR media ensures efficient oxygen transfer to the biofilm. Aeration systems in MBBR reactors help mix the media, maximizing oxygen diffusion, which is essential for aerobic bacteria to metabolize organic matter. This feature helps K1 media support both aerobic and anoxic treatment processes in different zones of the reactor.

Advantages of K1 MBBR Media

K1 media stands out among other bio media options for several key reasons, including its versatility, performance, and ease of use.

1. High Treatment Efficiency

One of the primary advantages of K1 media is its exceptional treatment efficiency. The high surface area and optimized biofilm environment allow the system to process a greater volume of wastewater while achieving higher pollutant removal rates. This makes it ideal for applications where high organic loads or stringent discharge requirements are present, such as industrial wastewater treatment and municipal plants.

2. Durability and Longevity

K1 MBBR media is designed for long-term operation. Made from HDPE, the media is resistant to wear, corrosion, and chemical degradation. This durability ensures that K1 media maintains its performance over time, reducing the need for frequent replacements and lowering the overall cost of ownership.

3. Adaptability to Different Treatment Objectives

K1 media is highly adaptable and can be used in various treatment configurations, including aerobic, anaerobic, and anoxic processes. This flexibility allows it to be integrated into different stages of wastewater treatment, addressing the specific needs of each system, whether it be organic matter reduction, nitrogen removal, or phosphorus removal.

4. Simple Installation and Maintenance

K1 media is easy to install in new or existing MBBR systems. It is modular, meaning that its volume can be adjusted according to the system’s capacity needs. Moreover, its continuous movement and self-cleaning nature significantly reduce the need for maintenance, as excess biofilm naturally detaches from the media, preventing clogging and maintaining system efficiency.

5. Cost-Effectiveness

Compared to other biological treatment systems, K1 MBBR media offers a cost-effective solution for wastewater treatment. Its high efficiency means that smaller reactors can be used to treat the same volume of wastewater, reducing capital costs. The media’s durability and low maintenance requirements further reduce operating expenses, making it an economically attractive option for both small and large-scale operations.

Comparison to Other Biofilm Technologies

K1 MBBR media has distinct advantages, but how does it compare to other biofilm technologies commonly used in wastewater treatment?

1. K1 MBBR Media vs. Random Packed Media

Random packed media, often used in trickling filters or rotating biological contactors (RBCs), consists of irregularly shaped materials that provide surface area for biofilm attachment. However, K1 MBBR media has a number of advantages:

- Surface Area: K1 media has a higher and more uniform surface area compared to random packed media, which increases treatment efficiency.

- Durability: Random packed media is often prone to breakage or degradation over time, whereas K1 media is highly durable and long-lasting.

- Mobility: K1 media is freely floating and moves continuously within the reactor, ensuring more consistent biofilm contact with the wastewater. In contrast, random packed media is stationary, which may lead to uneven treatment and potential clogging.

2. K1 MBBR Media vs. Fixed Bed Biofilm Reactors

Fixed bed biofilm reactors (FBBRs) use stationary media for biofilm growth, where wastewater flows over or through the media. While FBBRs have their own strengths, K1 MBBR media provides clear advantages:

- Self-Cleaning Mechanism: The continuous movement of K1 media prevents excess biofilm buildup, which can be a common problem in fixed bed systems. FBBRs often require manual cleaning to remove biofilm overgrowth.

- Load Flexibility: K1 MBBR media is better suited for handling variable organic loads, as the media’s mobility and large biofilm capacity allow the system to adjust to changing conditions more effectively.

- Footprint: MBBR systems using K1 media tend to have a smaller footprint compared to FBBRs, which require larger reactors to achieve similar treatment capacities.

3. K1 MBBR Media vs. Membrane Bioreactors (MBR)

Membrane bioreactors (MBRs) combine biological treatment with membrane filtration to achieve high levels of wastewater purification. While MBRs are highly effective, they come with certain challenges when compared to K1 MBBR media:

- Energy and Cost: MBR systems require significant energy for membrane filtration and aeration. In contrast, K1 media systems are more energy-efficient and have lower operational costs, making them more suitable for projects with budget constraints.

- Maintenance: Membrane fouling is a common issue in MBR systems, requiring frequent cleaning or membrane replacement. K1 MBBR media systems require less maintenance since the biofilm naturally sheds from the media.

- Complexity: MBR systems are more complex to operate and maintain, whereas MBBR systems using K1 media are simpler and more user-friendly.

Conclusion

K1 MBBR media continues to be a valuable asset in modern wastewater treatment technologies. Its high surface area, durability, and operational simplicity make it an ideal choice for systems requiring efficient and reliable pollutant removal. As environmental regulations tighten and demand for sustainable wastewater solutions increases in 2024, K1 MBBR media offers a competitive edge in terms of performance, cost-effectiveness, and adaptability to various treatment scenarios.

For environmental engineers tasked with designing or upgrading wastewater treatment plants, K1 MBBR media provides a proven and innovative solution that meets the needs of both current and future treatment challenges